.jpg)

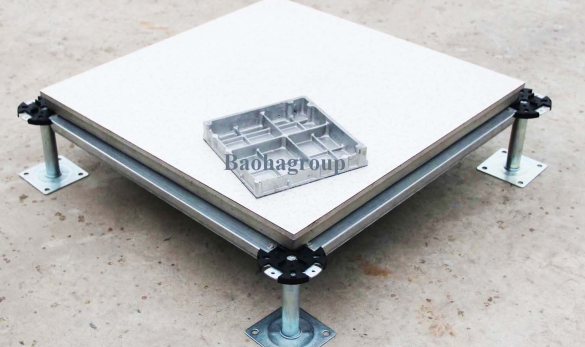

Aluminum Perforated raised floor

Aluminum Perforated Panel

Technical specifications

Aluminum Perforated Panel

Characteristics

●Existing solid panels can be refitted to perforated panels by applying ●Ventilation openings with standard drilling equipment

●Manufactured with the highest precision

●Class A1 building material (Non-combustible)

●Precisely drilled holes with chamfered edges

Covering Finishes

●PVC

●HPL

●Epoxy coating

●Ni-Cr plating

Ventilation Rate of Our Access Floor Airflow Tiles

-

Main Air Flow Rate of our Perforated Raised Floor : 50%

-

Other rate for option: 20%, 22%, 25%, 30%, 35%, 41%, 45% and 75%.

Applications

CTLINK All Steel Perforated Raised Floor combines with the characteristics and features of all steel access floor and perforated raised floor, it can be widely used in typical data centers, computer room, telecommunication rooms, electronic assembly areas, Cleanrooms in the field of research and production, Fields of research and production with low particles requirement, Assembly, conference and meeting rooms, Office areas (laminar air flow), general purpose equipment applications of access floor and more areas for air-conditioning of machinery.

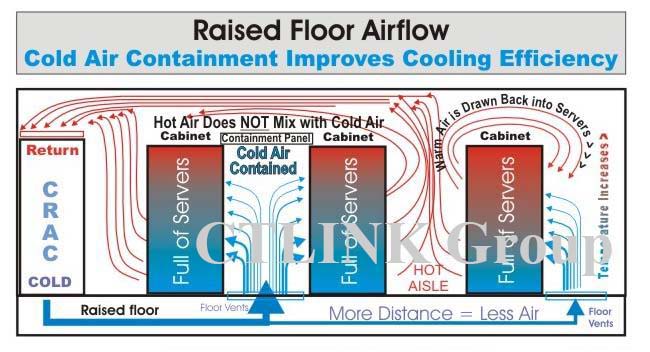

The combination of the perforated all steel raised floor tile and the replacement air conditioner form a cold air flow area, and the electrostatic floor is paved to form a bottom air supply passage, then air is blown in the passage between the machine room cabinets.

Related Products

Air Flow Control Valves: Adjust the ventilation rate

Air Distribution Unit: Adjust the air supply volume. A plurality of small fans are installed inside, and the operating state of the fan is automatically adjusted according to the temperature condition of the upper space, thereby producing a constant and controllable effect of maintaining the temperature of the floor production space.

Benefits

-

Allow for air flow distribution from under the raised access floor

-

Easy to adapt into your existing raised access floor system

-

Lightweight for ease of handling

-

Excellent ultimate load performance

-

Epoxy finish for lifetime protection

-

Interchangeable with other panel strengths

-

Completely non-combustible

-

Excellent grounding and electrical continuity

-

Flame spread and smoke development rating: Class A

-

High strength and durability

| System Performance Criteria (Tested on Actual Understructure) | ||||||||

| System Type | SYSTEM WEIGHT | STATIC LOAD | ROLLING LOAD | IMPACT LOAD | ||||

| Panel | Understructure | Design Load | Ultimate Load | Safety Factor | 10 Passes | 10,000 Passes | ||

| Aluminum Floor (AF1000) |

Bolted Stringer | 12.3bs/ft2 (60kg/m2) |

1250 lbs |

Min. 2000 lbs |

Min. 2 |

1000 lbs |

1000 lbs (454kg) |

150 lbs (68kg) |

Download Document

Product videos

Aluminum Perforated Panel

Characteristics

●Existing solid panels can be refitted to perforated panels by applying ●Ventilation openings with standard drilling equipment

●Manufactured with the highest precision

●Class A1 building material (Non-combustible)

●Precisely drilled holes with chamfered edges

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)