.jpg)

Anti-static HPL raised floor for data center

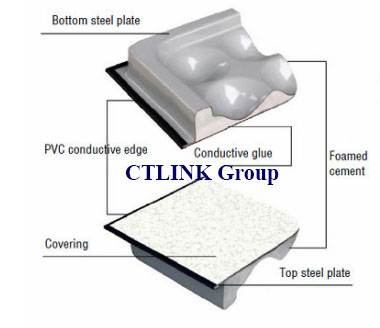

This product is made of quality steel plate, which is stretched forming, point welded and plastic sprayed with bubble cement filler filled in its inner cavity. The fire-resistant decoration plates that can endure high temperature adhere to its surface with conductive chips embedded around it. The pedestals and cross beams are wholly plated with zinc and the height of pedestals is adjustable and can be self-locked.

Technical specifications

CTLINK® RAISED ACCESS FLOOR SYSTEM

ANTI-STATIC HPL STEEL RAISED FLOOR

.jpg)

Drawing-of-HPL-steel-raised-floor Cutting-Edge-of-HPL-steel-raised-floor

This product is made of quality steel plate, which is stretched forming, point welded and plastic sprayed with bubble cement filler filled in its inner cavity. The fire-resistant decoration plates that can endure high temperature adhere to its surface with conductive chips embedded around it. The pedestals and cross beams are wholly plated with zinc and the height of pedestals is adjustable and can be self-locked.

HPL raised floor panels mean steel access floor with HPL coverings

CTLINK Raised floor are produced in strict accordance with industry standards and meet (pass) the internationally recognized CISCA Loading Test, as well as ASTM E84-01: Flame Spread 0 - Smoke Formation, ASTM E136, Non-combustible according to BS 476: Part 4: 1970, BS475 fire tests to ensure the long-term safety of each office flooring project which used our raised floor systems

Features of HPL steel raised floor

- Designed specially for computer room & clean room

- Excellent rolling load & ultimate load performance

- Light weight cementitious fill makes panels solid and quiet

- Completely non-combustible

- Black electrodeposition cathodic epoxy paint finish for life time protection

- Class A flame spread and smoke development rating

- Wide range of finishes available

Benefits of HPL steel raised floor:

- Excellent concentrated and rolling load performance

- Freely interchangeable between panels

- Epoxy powder coating for lifetime protection

- Concrete core make panel solid and quiet

- Superior ultimate load performance

- Completely non-combustible

- Excellent grounding and electrical continuity

- Flame spread and smoke development rating: Class A

Applicable Fields

Computer rooms, programmed control equipment rooms, electrical-controlled classrooms, places that have requirements of dust-proof and anti-static, and fields with aerial requirements.

Understructure of HPL steel raised floor:

Understructure can be customized with an electro-galvanized, gold chromatised, or electrophoretic coating.

Colors: Available in silver, yellow/tan, or black

Flat Head Steel Pedestal

The pedestal design utilizes a 75mm square head. The base plate is normally 100mm square and includes provision for the use of mechanical fixing to the sub-floor or adhesive. The pedestal head design allows for the use of bolt-on stringers if required. All components are free of electro-zinc, a potential source of zinc whiskers.

Pedestal Height: 80mm -1500mm. Each pedestal allows for approximately 15mm-25mm height adjustment.

Pedestal Types:

Pedestal-F01

Specially designed for finished panels below 130mm height

as standard pedestals.

Specification:

- Flat pedestal head size 75x75x3mm, Rob M18

- Square Base Plate size 100x100x2mm

Pedestal-F02

Specially designed for finished panels above150mm height

as standard pedestals.

Specification:

- Flat pedestal head size 75x75x3mm, Rob M18

- Square Base Plate size 100x100x2mm

- Tube 1: D22mm tube*1.2/ 1.5mm Thick Wall/ M18 Screw

- Tube 2: 25mm tube*1.2/ 1.5/ 1.8mm Thick Wall/ M18 Screw

Above types of tubes should be available according to your requirements.

Pedestal-F03.jpg)

Specially designed for finished floor height from 400-2500mm as standard pedestals.

Specification:

- The pedestals can provide ±40mm vertical adjustment. It includes a locking nut to offer a locking facility after adjustment, ensuring no movement in the head

- Material: ≥ 5µm Galvanized steel

- Top plate: 75x75x3mm/ M18 screw

- Base plate: 100x100mm/ 125x125mm, Thickness 2.0/ 2.5/ 3.0mm

- Tube 1: Ø32mm, Thick wall 1.2/1.4/1.8mm

- Tube 2: Ø38mm, Thick wall 1.2/1.4/1.8mm

- Above pedestal type should be available according to your requirements. Plastic gasket and galvanized inner wall can be optional

Stringer ST for 600x600mm Rigid Grid System

- Material: ≥ 5µm Zinc galvanizing/ Hot-dip galvanizing/ Powder coated steel, and galvanized inner wall can be optional.

- Standard size:

- ST-540: 20x30x540mṃ

- ST-570: 20x30x570mm

- ST-1170: 20x30x1170mm

- Thickness: 0,8mm(standard)/ 1.0mm

- The Stringer needs to be pasted and sealed with 0.5mm thickness rubber tape for buffer

- Raised Floor Stringer ST is tested in accordance with the test procedures set forth in Ceilings & Interior Systems Construction

- Association CISCA A/F, Section 4 and European Standard En12825. The raised floor stringer ST is capable of withstanding 2000N, 203kgf axial load per stringer.

- The whole raised floor understructure includes pedestal and stringer ST.

Stringer ST-570 Strigner ST-1170

PERFORMANCE SELECTION CHART OF ANTI-STATIC HPL STEEL RAISED FLOOR SYSTEM

|

Panel surface |

HPL |

|

Size |

600 x 600mm |

|

Thickness in mm |

35 |

|

Fire Rating |

1 |

|

Top Steel Sheet in (mm) |

0.7-1.2 |

|

Bottom Steel Sheet in (mm) |

0.9-1.4 |

|

Safty factor |

>= 3 |

|

Defletion |

<= 2.5mm |

|

|

|

|

CONCENTRATED LOAD |

|

|

|

|

|

|

|

|

|||

|

|

UNTIMTE LOAD |

DEFLECTION |

UNIFORM LOAD |

IMPACT LOAD |

ROLLING LOADS |

|||||||||

|

PANEL |

0.100"/2.5mm |

0.080"/2.0mm |

10 PASS |

10K PASS |

||||||||||

|

(lb) |

(kN) |

(lb) |

(kN) |

(lb) |

(kN) |

(lb/㎡) |

(kN/㎡) |

(lb) |

(kg) |

(lb.) |

(kN) |

(lb) |

(kN) |

|

|

FS 700 |

2300 |

10.224 |

700 |

3.112 |

650 |

2.889 |

2500 |

11.113 |

100 |

45 |

650 |

2.889 |

450 |

2.000 |

|

FS 800 |

2600 |

11.558 |

800 |

3.556 |

750 |

3.334 |

2800 |

12.447 |

100 |

45 |

750 |

3.334 |

550 |

2.445 |

|

FS 1000 |

3300 |

14.669 |

1000 |

4.445 |

800 |

3.556 |

3500 |

15.558 |

150 |

68 |

800 |

3.556 |

600 |

2.667 |

|

FS 1250 |

3800 |

16.892 |

1250 |

5.557 |

1000 |

4.445 |

4000 |

17.781 |

250 |

68 |

1000 |

4.445 |

800 |

3.556 |

|

FS 1500 |

5000 |

22.226 |

1500 |

6.668 |

1250 |

5.557 |

5200 |

23.115 |

150 |

68 |

1250 |

5.557 |

1000 |

4.445 |

|

FS 2000 |

6000 |

26.672 |

2000 |

8.891 |

1500 |

6.668 |

6200 |

27.561 |

175 |

79 |

1500 |

6.668 |

1200 |

5.334 |

|

CTLINK Bolted Stringer System for Anti-static Cementitious Infill Steel Access Floor - Pedestal/Stringer |

||||||

|

Pedestal No. |

Pedestal Height (mm) |

Horizontal Load (kG) |

Vertical Load (18 kN) |

Pedestal Head |

Pedestal Tube |

Pedestal Base |

|

FS-L-PST80 |

80 ± 20 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST100 |

100 ± 20 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST150 |

150 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST200 |

200 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST250 |

250 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST300 |

300 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST350 |

350 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST400 |

400 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 22mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST450 |

450 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST500 |

500 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST550 |

550 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST600 |

600 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST650 |

650 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST700 |

700 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST750 |

750 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x2mm thick |

|

FS-L-PST800 |

800 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x3mm thick |

|

FS-L-PST850 |

850 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x3mm thick |

|

FS-L-PST900 |

900 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 25mmx1.2mm thick |

□100x100x3mm thick |

|

FS-L-PST400 |

400 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 32mm × 1.5mm thick |

□100x100x3mm thick |

|

FS-L-PST600 |

600 ± 25 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 32mm × 1.5mm thick |

□100x100x3mm thick |

|

FS-L-PST800 |

800 ± 03 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 32mm × 1.5mm thick |

□100x100x3mm thick |

|

FS-L-PST1000 |

1000 ± 30 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 32mm × 1.5mm thick |

□100x100x3mm thick |

|

FS-L-PST1200 |

1200 ± 30 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 32mm × 1.5mm thick |

□100x100x3mm thick |

|

FS-L-PST1400 |

1400 ± 30 |

50 |

Did not collapse |

□75x75x3mm flat |

Ф 32mm × 1.5mm thick |

□100x100x3mm thick |

|

Stringer No. |

Stringer Length |

Vertical Load (2000N) |

Tube Thick |

Tube |

||

|

ST |

570 mm |

Did not collapse |

1.0 mm |

□30 × 20 mm |

||

HPL Covering:

The size of HPL Tiles: 600*600*0.7/1.0/1.2/1.5(mm)

Why an Access Floor?

- Construction programmes are reduced by at least two weeks per floor due to elimination of a sand cement screed.

- As warm air rises, considerable cost savings are achieved by an underfloor air plenum delivering conditioned air exactly where it is needed - compared with the traditional uneconomic alternative of forcing conditioned air from the ceiling.

- Maximum flexibility for the installation and reconfiguring of services to equipment and workstations a matter of hours.

- In new construction the use of an access floor for total service distribution reduces the overall building height by about 13%. Or, for the same height, you can increase the number of floors.

_cr_845x506.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_480x480.jpg)

_cr_585x347.jpg)

_cr_585x347.jpg)

_cr_585x347.jpg)

_cr_585x347.jpg)